Vought F-8E Crusader "Limited Edition"

Eduard (ED11110)

1:48

Started: Jun 2017

Finished: Jun 2018

Link to Gallery

The Vought F-8 Crusader was a single-engine, supersonic, carrier-based air superiority jet aircraft built by Vought for the United States Navy and Marine Corps, replacing the Vought F7U Cutlass, and for the French Navy. The first F-8 prototype was ready for flight in February 1955. The F-8 served principally in the Vietnam War. The Crusader was the last American fighter with guns as the primary weapon, earning it the title "The Last of the Gunfighters".

For my build of the Eduard F-8E 'Limited Edition' kit I decided to use the provided Furball markings for Marine Fighter Attack Squadron 235 (VMFA-235) 'Death Angels' during the Vietnam War. I was inspired by the picture below of a very grubby VMFA-235 F-8E with a full bomb load and the pilot prepping for a mission. I like that the wing is in the up position and the flaps and slats are fully deployed.

Fixed Wing Marine Fighter (All Weather) Squadron VMF(AW)-235 deployed to Vietnam on February 1, 1966 flying the F-8E Crusader. VMF(AW)-235 had pilots in the air flying their first combat sortie less than 24 hours after arriving and had flown 603 sorties by the end of the first month. The squadron's working components smoothed out by March and the pilots established a new monthly operational record of 806 sorties and 1,027.8 flight hours.

Keeping busy, the Angels flew 696 sorties in April, 663 in May and 678 in June. On 10 June the squadron set a new record of 41 sorties in a 24-hour period. The only land-based F8E Crusader-equipped squadron in Vietnam in 1966, the squadron hammered the North Vietnamese heavily, flying over 6,000 sorties and encompassing over 7,000 flying hours in support of 22 special operations.

On 15 November 1966 the Angels departed Danang for MCAS Iwakuni (Japan), arriving 17 November, where it joined MAG-15 and the 9th Marine Amphibious Brigade. They returned to Vietnam on February 15, 1967 this time for over a year until May 11, 1968. They were the last active duty Crusader squadron and upon leaving Vietnam the squadron moved to Marine Corps Air Station Kaneohe Bay. On September 6, 1968 they were redesignated Fixed Wing Marine Fighter Attack Squadron VMFA-235 and equipped with the F-4 Phantom.

KIT OVERVIEW - Eduard 1:48 F-8E Crusader (ED11110)

Going into this build I had some knowledge of the issues with the Hasegawa kit upon which the Eduard boxing was based. I had never actually gotten around to building any of my Hasegawa kits but had accumulated a substantial collection of PE and resin accessories to address many of the kits shortcomings. Given that this was a review build of the specific Eduard boxing I wanted to try and minimise the use of other addons but figured that it would be ok to utilise any of the Eduard extras that were available but just not included in this particular boxing. I previously did an in-depth box review of the Eduard F-8E release if you are looking for more details on what is in the box.

To that end I purchased the following 'extras' to use in my build:

- Eduard Brassin Crusader Exhaust Nozzle 1/48 Cat.No 648302

- Eduard Brassin Crusader Air Intakes 1/48 Cat.No. 648301

- Eduard Brassin Mk.82 bombs 1/48 Cat.No. 648093

- Aerobonus MER (Multiple Ejector Racks) 1/48 Cat.No. 480057

- Aerobonus US Navy fighter pilot with ejection seat for F-8E/H/J/K Crusader 1/48 Cat.No. 480075

I resisted the urge to purchase any additional photo-etch sets because this kit came with a couple of small frets which covered off the cockpit (pre-painted) and some external paneling. It's too easy these days to go overboard and purchase everything thats our there for a kit, "just because".

There are also several small corrections that you can make to the Hasegawa kit which do not really require any aftermarket. I uncovered many of these by digging through old forum posts, which turned out to be well worth the effort. By far the best post I found was on ARC where a former F-8 pilot (Superheat) provided much insight. I have taken the liberty of summarising the main points he raised here and in general these corrections could be grouped into one of three categories as follows:

Hasegawa F-8 (Any Variant) Corrections

- There is a hump on the upper wing at the wingfold which should not be there (the underside is correct)

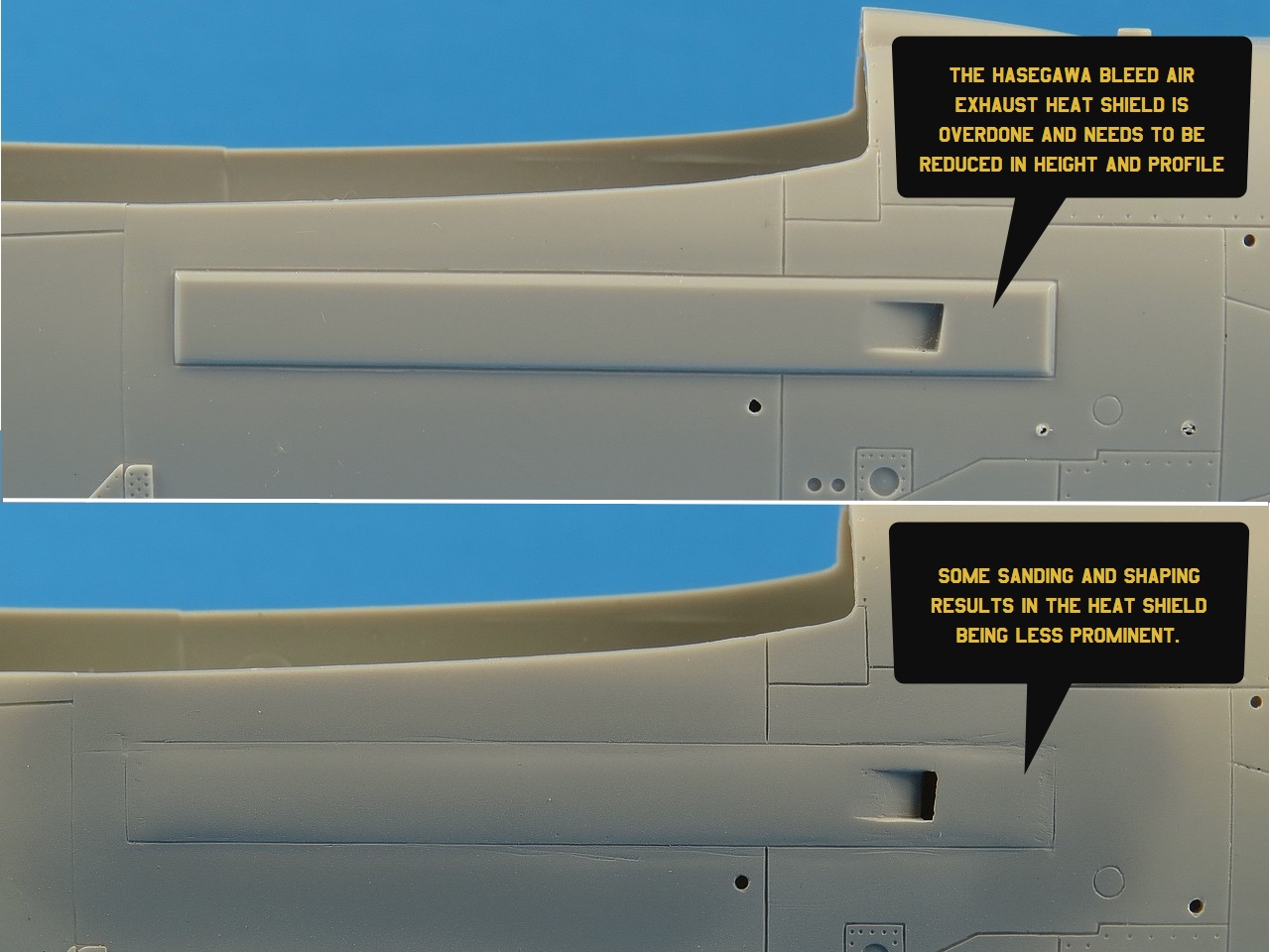

- The rectangular bleed air exhaust heat shield on the right side is not correctly rendered, it is not a flat plank applied to the side, but curves down to meet the fuselage and the panel is applied over the fuselage, not butt-joined

- The radar screen is incorrectly angled for a production F-8. Production aircraft had a conventionally mounted screen, ie parallel to the instrument panel.

- The panels on either side of the nose with the cooling vents do not stand proud of the fuselage as in the kit.

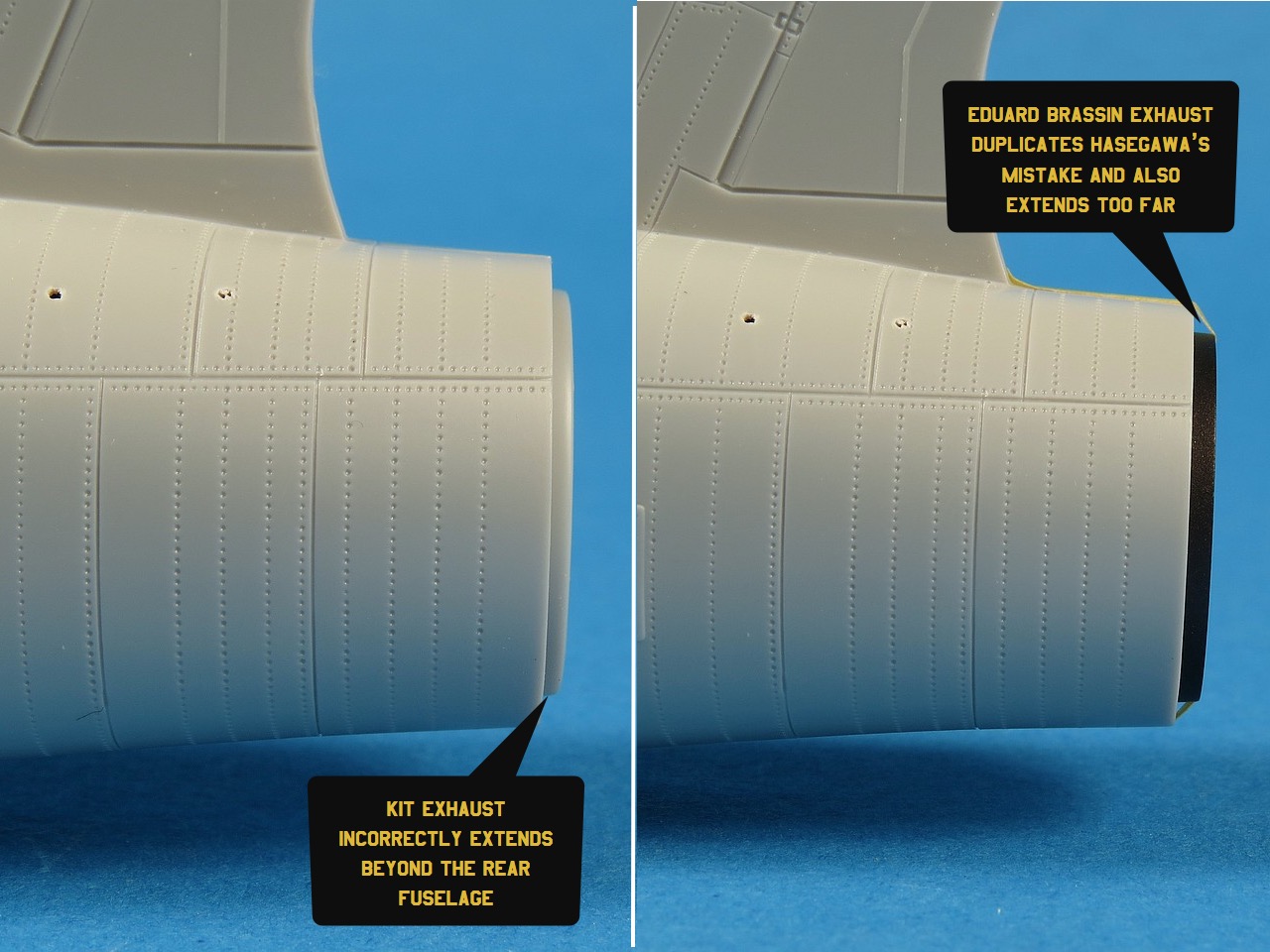

- The AB nozzle should not stick out past the lip of the tailcone as it does in the kit.

- The catapault keel pin and its recess between the speed brakes is missing.

Hasegawa F-8E Corrections

- Cut off the nose gear cable deflector horns

- Remove the BLC (Boundary Layer Control) ducts on the ailerons, but leave a bit of a notch in the leading edge as these are also the hinge points

- The kit seat is not great but is a reasonable start toward an accurate F5 seat, correct for the E

- The early E's did not have the "Bullpup" fairing on the upper wing/fuselage and also did not have any ECM antenna on the tail

Hasegawa F-8J Corrections

- Trim off the center flange on the main gear struts

- Cut out the straight center section of the rectangular arrestor hook shank and replace it with round stock and fair it into the mount and hook point

- Replace the seat with an F7

- The J, as did most rebuilds, had two fairing on the lower fuselage between the main gear doors. (Wolfpack Designs' F-8 Exterior set has them)

- All J sqns had the larger ECM antenna on the tail, except VF-162, the first squadron to deploy with the J, had the smaller one.

- Be sure you use the double droop (leading edge slats) and the larger horizontal stabs

Looking through these lists I am sure many of you will think that some of these items are not worth worrying about and I agree. I decided to tackle the most noticable ones and/or the easiest ones.

BUILD - Eduard 1:48 F-8E Crusader (ED11110)

As usual, construction begins with the cockpit. Eduard has provided a full pre-painted interior PE fret and as this saves a lot of work. The IP and side consoles are nicely pre-painted whilst the other brass details are unpainted. I like to dry fit all components prior to applying glue and small sections of tape are ideal for holding things in place.

In addition to the PE goodies provided in the box I wanted to add some more detail to the cockpit area. First up was some rails for the ejection seat. Hasegawa never provided these in the base kit, nor did Eduard with its Brasin seat and finally AeroBonus left these off their otherwise excellent pilot and seat. I maintain on hand a pretty good range of Evergreen Styrene plastic and selected a suitable H column section that more or less matched the shape of the ejection seat rails in the F-8.

I had also noticed in reference photos that there is an equipment compartment behind the cockpit and figured that it was a small scratchbuilding job to open this up. The final small adjustment needed was to alter the position of the

pilots left hand as I wanted to have him holding a map, rather than a throttle. This was super easy as I just cut it off at the wrist and super glued back on.

Once the glue was dry on the compartment walls I filled it up with plumbing and wiring by using 0.3mmm lead wire fastened with super glue. The large oxygen tank was made from tubular rod cut and sanded to shape. I realise that very little of this will be seen once the canopy is on.

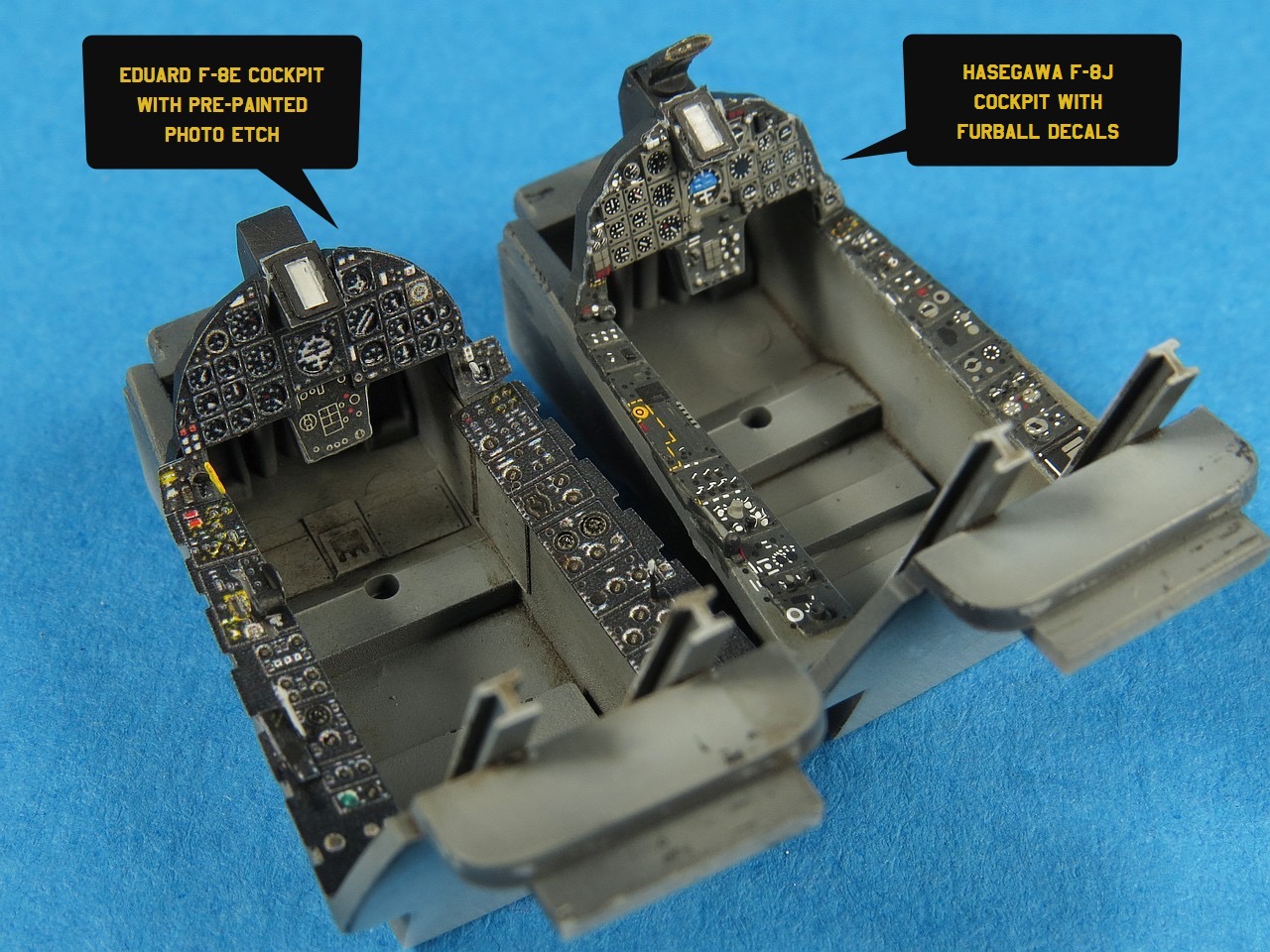

Before starting this Eduard kit I decided to try and take on a dual F-8 build. I hoped this would enable me to more efficiently punch out two finished F-8's, the first an F-8E (using the Eduard boxing) the second an F-8J (using the Hasegawa boxing). As I was using the PE detail set for the F-8E this left the Furball decals from the Eduard boxing available to use on the F-8J cockpit. Much to my surprise the instrument panel decal shattered when placed in water. Luckily it was not fatal and I was able to recover the pieces.

The two completed cockpits shown side by side give a good idea of the differences between pre-painted PE and plain old decals. I think the PE does look more convincing for the instrument panel but in general I think this demonstrates that you can comfortably get away with using decals in 1/48 scale. It's worth noting that I did not remove any of the raised detail on the plastic parts for the F-8J cockpit (I did sand the F-8E flat prior to gluing the PE of course).

Are you enjoying and finding value in this content? If so, please consider supporting my work by Buying Me A Coffee. Your support ensures that I can continue to provide high-quality, accessible content now and in the future, keeping this space free from distractions and focused entirely on the hobby we all love. Every little bit helps, and I truly appreciate your generosity!

One of the final tasks to close out the cockpit work was to paint the equipment bay behind the cockpit tub. The oxygen tank (as is standard) is painted a distinctive grass green color and the piping and wiring picked out with Citadel Silver.

Ever trying to improve my figure painting skills I turned to a couple of online tutorials and was happy enough with the end result. These AeroBonus figures are really nicely detailed and look realistic as they come moulded into the seat with belts. Its a bit more fiddly to paint the seat and pilot but a steady hand and patience get it done. I used the Eduard pre-painted headrest pull-handle as the AeroBonus resin part was deformed. The folded map is just downloaded from the internet and printed on normal paper which means it looks a bit overscale when viewed from the side but once in the cockpit looking down should be fine.

The first Hasegawa design problem I decided to tackle was the canopy hinge. If you want to display the canopy down on the F-8 kit its a great fit. If however you want to have the canopy open you run into problems. This stems from Hasegawa moulding the hinge 'ears' at such an angle so that you can't just rotate the canopy up without the 'ears' being distorted. I though about a few options and in the end decided that it was cleanest to just cut off the kit 'ears' and make up my own. I also thinned out the canopy frame plastic at the very top so that when open it would not hit the fuselage.

A test fit of the modified canopy was successful. I was able to raise the canopy to an accurate angle and my new hinges were snug enough to hold it without any braces or glue. I also did some test fitting of the AeroBonus pilot/seat and had to trim a little of the bottom to get him to sit right

With the cockpit now pretty much done it was time to work on other items so I could seal up the fuselage. First item on my checklist was to see what could be done to remove the raised panel on the nose section. Before sanding down the raised section I used my scriber tool to trace the outline so that I would still have panel lines. I protected the surrounding area with tape and carefully sanded down the panel and replaced the rivets. In hindsight I probably would not worry about this again as it did result in the vents being too shallow and my panel lines are not that neat.

The rectangular bleed air exhaust heat shield on the right fuselage side is not correctly rendered. Hasegawa have moulded it as raised 'plank' when in fact it is much more subtle and blends into the fuselage rather than butts out from it. Some sanding and scraping can help tone down this panel to more realistic finish.

Early F-8E's were not fitted with the ECM blister on the vertical tail. The Hasegawa kit comes with the blister moulded on and so for any aircraft you model that had no blister you are required to manually remove it (FYI, the F-8J had a much larger blister on the tail and Hasegawa does provide it in their J boxing, but you also need to remove the smaller moulded on detail for that build). There is plenty of surface detail around this area (including some raised) so work carefully and use masking tape to help protect the surrounding detail. As an aside, of the five F-8E marking options in the included Furball sheet only one of them has the ECM blister

It was getting time to start thinking about joining the fuselage. There are quite a few sub assemblies to be placed inside this model and I find its a good idea to test fit and adjust as many times as needed to get things aligned properly. The intake trunking is a great fit and I simply painted the inside white before gluing the top and bottom halves together. Once dry I sanded the front end as best I could using wet n dry abrasive wrapped around a wooden cocktail stick. The main wheel well and compartment under the upper wing will be painted after I join the fuselage so these just need to be assembled as this point.

As expected from a Hasegawa kit the fit of the internal subassemblies is snug and alignment spot on. I do have a couple of the Aires resin wheel wells but was not in the mood to have to deal with this so left it for a future build.

I obtained the optional Eduard Brassin Exhaust Nozzle (Cat.No 648302) and found a couple of surprising issues with it. It is designed to be a drop in replacement for the kit plastic exhaust which can be inserted into the rear fuselage after it has been assembled (this appealed to me). Both the kit plastic and Eduard Brassin exhaust have rectangular guide rails along the side. These help ensure the exhaust aligns properly in the fuselage.

The problem is that Eduard has moulded their guide rail along the full length of the exhaust tube and this means that when inserted it is obstructed by the moulded on poly-cap bracket designed by Hasegawa to be the horizontal tail mounting point. The Eduard instructions tell you to cut off this poly cap braket (say what !!) and then their resin exhaust will slide nicely into place. Well that may be one option Eduard but how exactly would we now secure the two horizontal tails to the fuselage once you have us remove the bracket and polycap ?? That's definitely Strike 1.

A much better solution is to use your knife to trim about 5mm off the very end of the resin guide rail, that way it won't hit the kits bracket. Eduard really didn't think this one through and should have designed their resin this way in the first place.

Strike 2 for the Eduard Brassin Exhaust is that they made the same mistake that Hasegawa made for the length of the nozzle. The plastic kit exhaust incorrectly extends (about 2mm) beyond the rear of the aircraft fuselage skin. This is wrong (it should be flush) and unfortunately Eduard copied the kit part too closely without doing their homework. I also have the Aires resin nozzle and they got it right (on both counts).

With all internal work now complete I joined the fuselage and sanded the seams flush. The Hasegawa F-8 (and A-7) kits have a known problem with the very badly moulded surface detail (panel lines and rivets) on the lower fuselage. In places this is so bad that the surface detail just does not exist or is just a faint outline. This meant it was time to break out my trusty Tamiya scriber and vinyl tape.

Because the existing panel lines were so bad I chose to fill what was there with super (CA) glue and sand completely flush. This have me a clean surface on which to layout and scribe the new panel lines. I find this is easier in the long run than trying to restore what is there and ending up having inconsistent results.

This photo probably shows best just how bad the surface detail is on the Hasegawa moulding. If I had to guess I'd say that Hasegawa was contracted by Eduard to mould the plastic sprues for their boxing as it seems to use the newer (softer) plastic that Hasegawa has switched to in recent years. This still did not alleviate the moulding problem and I had to remove and re-create the panel detail as shown here. The Eduard kit fuselage is on the bottom (after my scribing work) whilst the top is one of my older Hasegawa kits.

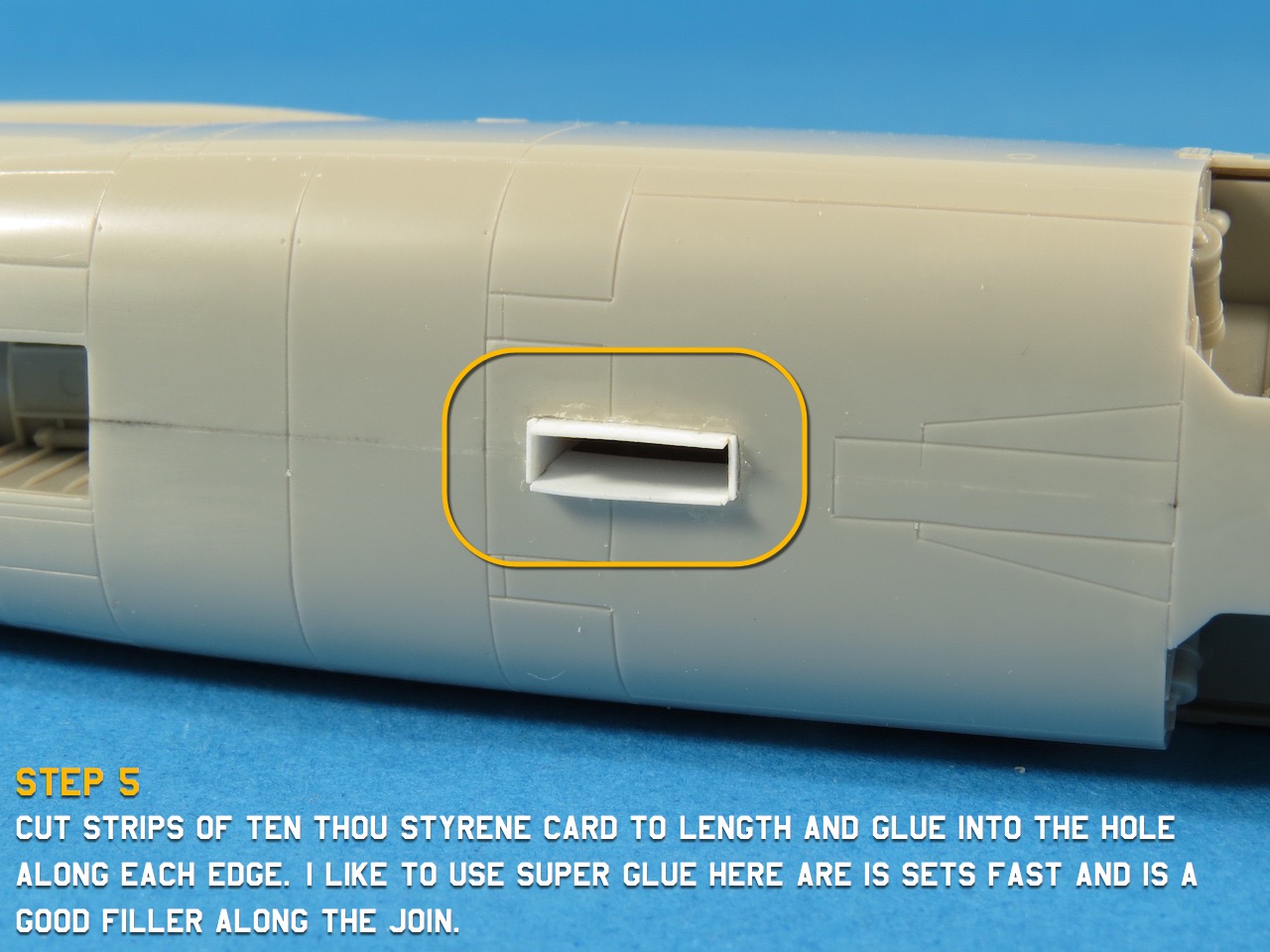

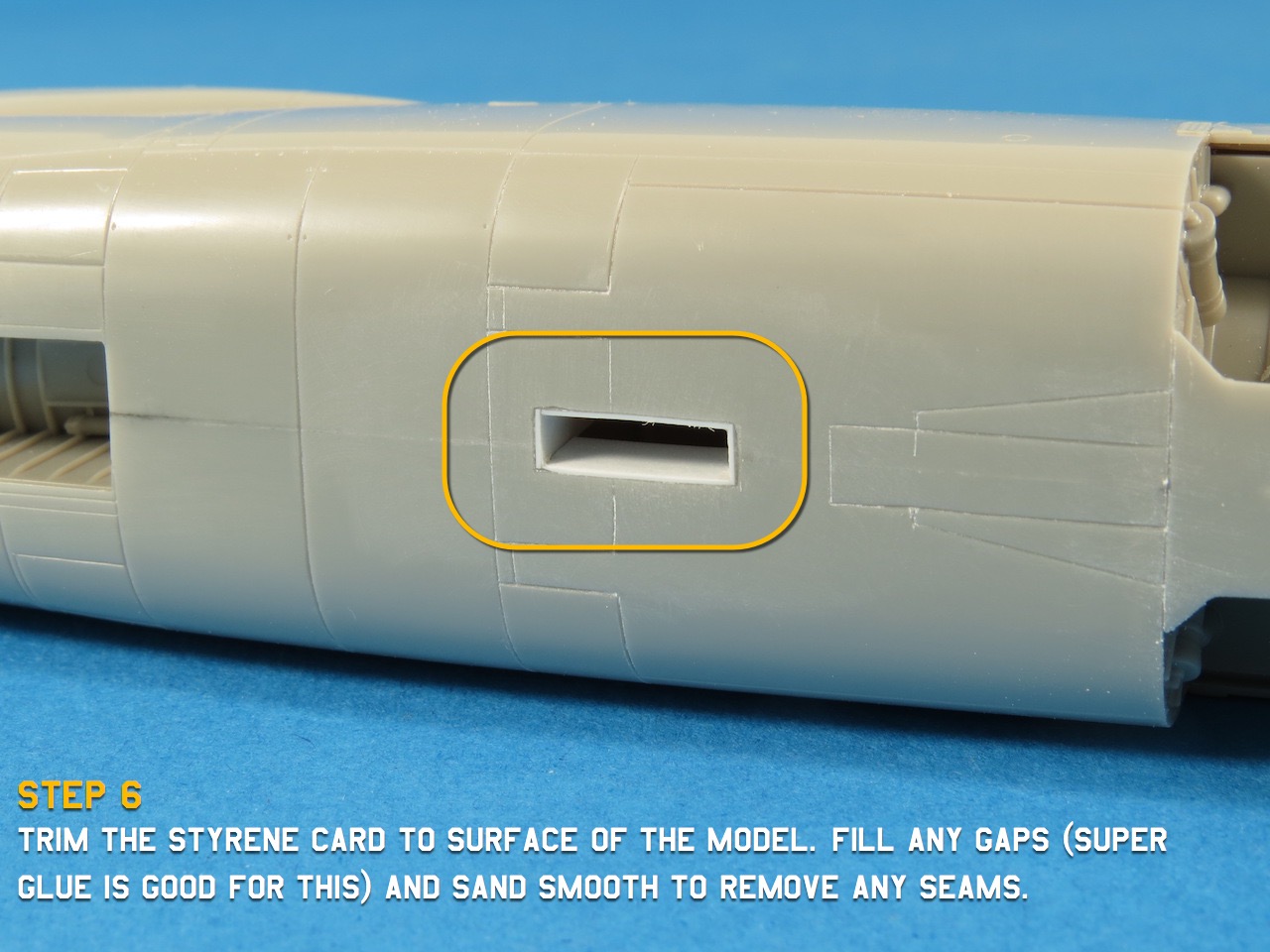

Another minor omission by Hasegawa in their 1/48 Crusader is the rectangular recessed housing tucked in between the speed brake arms. This housing holds the catapult attachment point which was used in early carrier aviation when the steam catapult was attached, via a bridle cable, to the airframe directly rather than to the nose wheel strut as today. Adding this small housing was an interesting scatch-building project and an opportunity for me to do a step-by-step guide.

Are you enjoying and finding value in this content? If so, please consider supporting my work by Buying Me A Coffee. Your support ensures that I can continue to provide high-quality, accessible content now and in the future, keeping this space free from distractions and focused entirely on the hobby we all love. Every little bit helps, and I truly appreciate your generosity!

One of the nice things about the Eduard Limited Edition boxings is that they include many of the photo etch and resin goodies that Eduard have created for the base kit, in this case the Hasegawa F-8. As I plan to display the wing in the open position the extra detail provided by the PE parts, both internal and external, is quite welcome as the plastic parts are fairly basic. When working with unpainted PE I like to lightly abrade the brass surface with some fine wet n dry paper. This helps later with paint adhesion and also helps the CA glue adhere to the brass.

To test my work and prepare the brass and plastic parts for later paint coats I have applied a generous coat of Tamiya Fine Grey primer. Note also the extra rivet surface detail that has been added around the top panels.

The PE set also includes several replacement panels for the fuselage underside which help enhance the various access panels found here. I prefer to use slow setting CA glue for parts like these as it gives more time to get them aligned properly. Many of the panel lines seen here have been added by me as the kit plastic detailing was so shallow or distorted I sanded it off.

When adding recessed rivet detail there are several methods I like to use to ensure the rivets are properly spaced. You can of course use a rivet wheel, but when the rivets needed are very widely spaced the wheels are not much use. One tip is to use a ruler to mark out the spacing you want onto a piece of tape. Lay the tape on the surface of the model where the rivets are required and then use a sharp tool or pin to add the rivets using the edge of the tape as a guide. This is a particularly useful technique for laying out rivets on curved surfaces as the tape marks ensure the spacing is consistent around the curvature.

For laying down rows of rivets as found on the metal skin of aircraft, there is no better tool than a good quality wheel set. I like to use the Rivet-R Mini from RB Productions. These are made from photo etch steel and are very precise. The wheels come with a holder designed to fit a standard knife handle and you can purchase additional holders for each sized wheel. RB produce wheels with rivet spacings ranging from 0.55mm to 1.50mm. For the rivets on the Crusader wing I use both the 0.75mm and 1.0mm wheels as I find this look best for 1/48 scale.

The control surfaces (flaps and slats) have received their own rivet runs. There are many techniques to achieve nice straight lines when using the wheel. I find that laying down a strip of masking tape along the line you want to rivet and using its edge as a visual guide to sight along when rolling the wheel works very well.

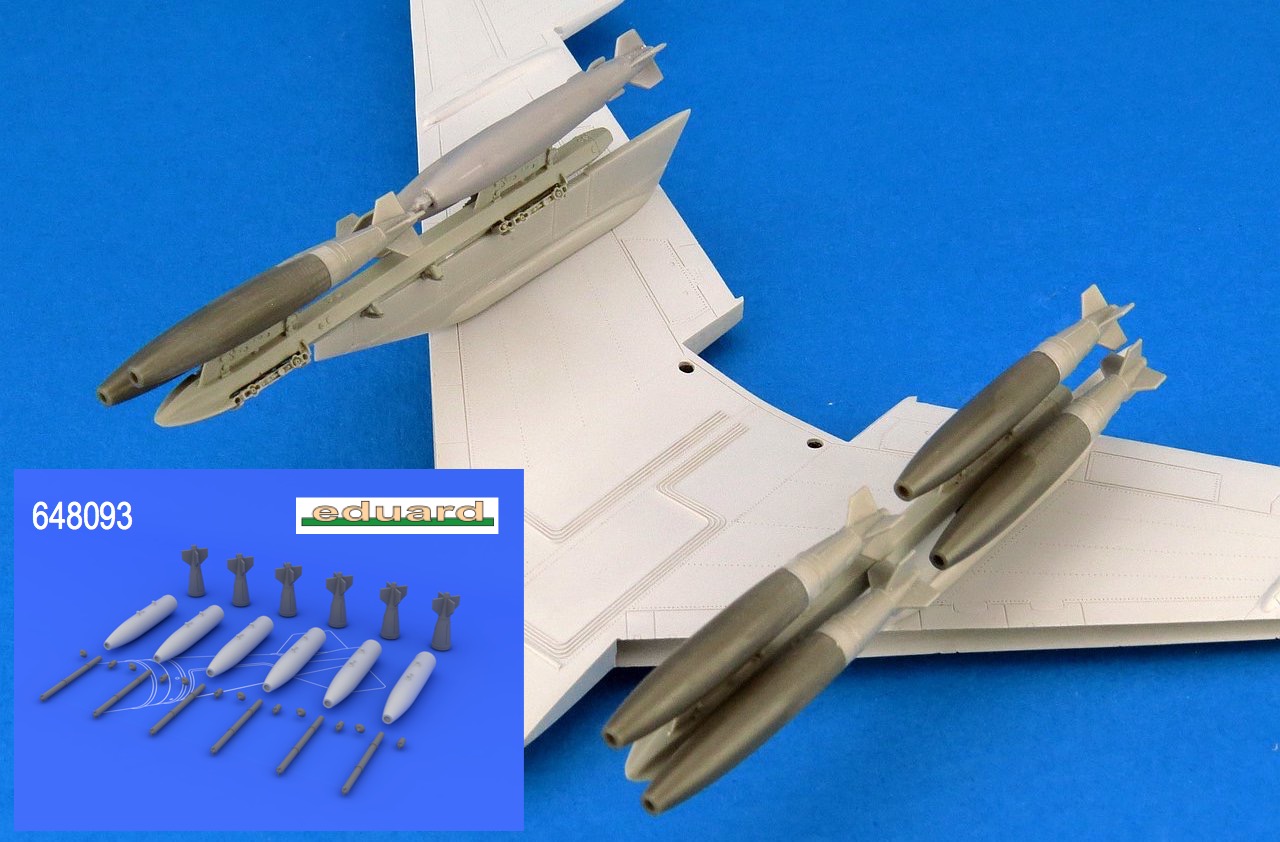

Once the surface detailing work was complete I turned my attention to the stores and weapons. In this case I plan to have a full bomb load on this USMC Crusader. The kit does come with the wing pylons but in typical Hasegawa fashion no actual weapons are included on the kit sprues. It would have been nice to see Eduard throw in some of its very nice Brassin weapons as these would help ease the pain of the cost of these limited edition kits. I sourced a MER (Multiple Ejection Rack) from Aerobonus and a pack of six Mk.82 bombs from Eduard. I like to pin (using brass) all bombs onto their pylons for strength and to ensure perfect alignment. Nothing looks more distracting than that one crooked bomb. Copper wire was used to add some of the control wires found on the MER.

A wider shot of the finished MER. The rack is designed to carry 6 bombs but when used on the F-8 was only loaded with 4 bombs. This was due to the Crusaders wing pylons being very close to the fuselage and any inner bombs could not be carried safely. It was necessary for me to adjust the mounting points on the Aerobonus MER in order to fit the Hasegawa pylon. To do this I moved the aft mount on the MER forward by about 5mm. You can see in the picture the white plastic I used to fill the hole left from the original location.

Each Mk.82 bomb was drilled and fitted to the brass pins on the MER. The forward bombs shown here are the two part resin Eduard Brassin items and the aft bombs are from the Hasegawa Weapon set. Note the ejection pins marks on the pylon which have been filled with Tamiya Basic Putty. Also note once again the original location of the MER aft pylon mounting sway brace (the small white chip). In case you are wondering what the pencil X's mean they are to remind me which side I needed to drill and pin with brass (ie the outer mounts only on each side).

A test fit of the in-progress pylon, MER and bombs to check the alignment is correct. Now is the time to discover problems and rectify them before we get too far advanced.

Here is the full load of eight Mk.82's on the two MER's. If you are wondering why I used two of the plastic Hasegawa bombs it's because the Eduard Brassin packs come with six bombs and I needed a total of eight.

As a postscript to the pylon and MER work it was not until I had proceeded to the painting stage that I discovered that the early Crusader (and Skyhawks) used a MBR (McDonnell Bomb Rack) and not a MER. Luckily the difference between the two was minor and only required me to reshape the aerodynamic fairing on the nose of the MER. The Aerobonus resin is fairly soft and so it was an easy to shave with a knife and then sand smooth.

When sanding seams it's often unavoidable to loose some of the surface detail. The very rear of the Crusader fuselage is covered in many rivets and to make it easier to see what detail needed repair I applied a diluted mix of black ink. The ink is very thin and easily cleaned off with water after just a few minutes. As you can see it's dark enough to clearly see the location of each and every rivet to allow me to check those that need attention. As you work you can apply subsequent coats of ink to check your progress.

The cockpit shroud in the Crusader has a canvas boot that covers the area in and around the HUD. I was going to make one up from Milliput but when digging through my spares box found an old resin detail set from KMC designed for the Monogram Crusader kit. It had a very nice canvas boot and so I liberated this part from the set (I never intend to build a Monogram F-8 anyway). The resin part was slightly damaged and so I repaired it with some Tamiya Two part epoxy putty.

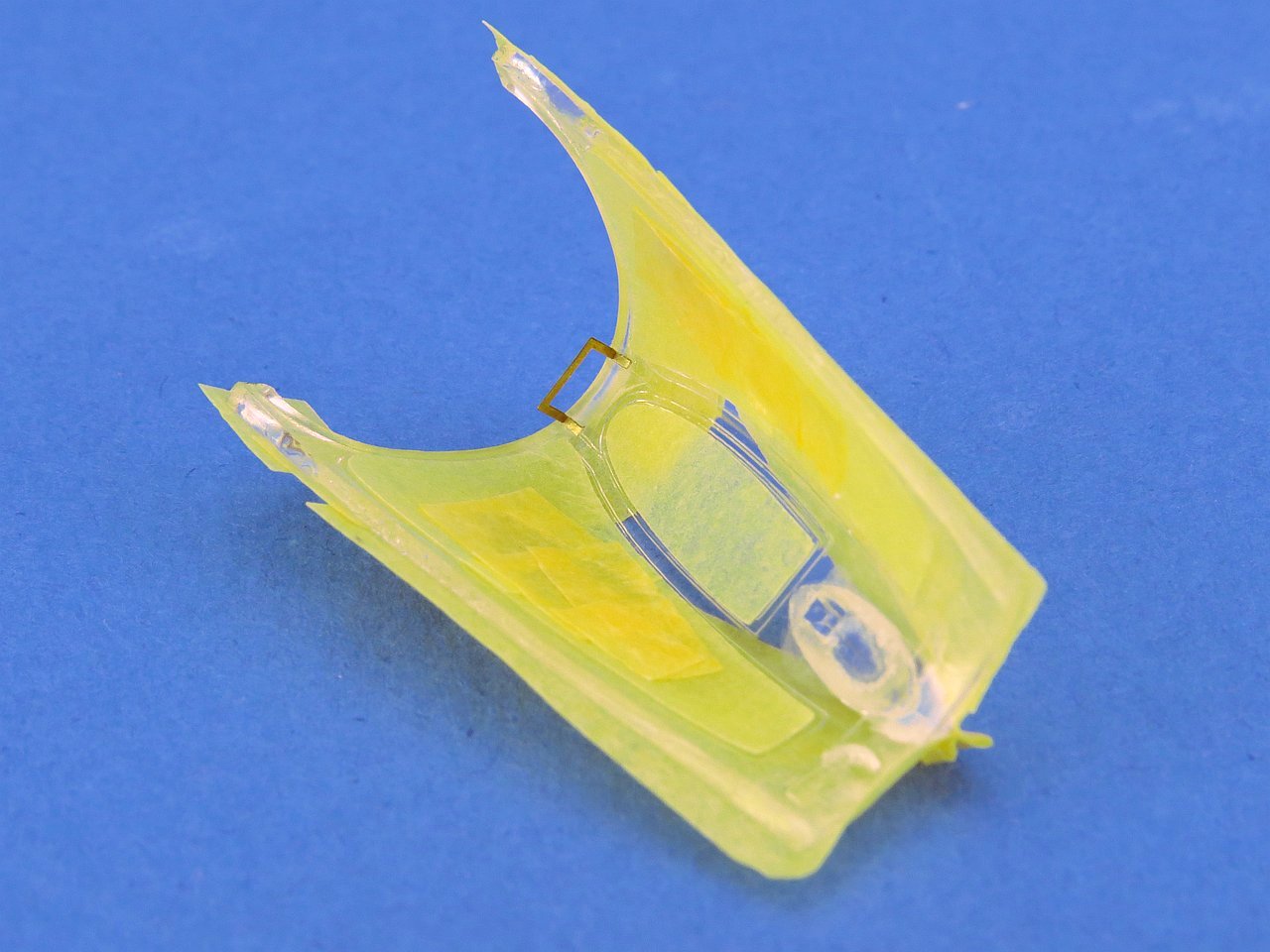

Before fitting the windshield I wanted to paint the interior framing. Eduard provide one of their pre-cut masking sets in this Limited Edition boxing and so I was able to save myself some time by using this. A small brass grab handle is also carefully attached using CA glue. The interior parts where painted with Tamiya XF-85 Rubber Black

Final touches and photo etch parts are fitted to the cockpit sidewalls and rear shelf just in time for masking. I'm not normally a huge fan of pre-painted color photo etch but in this case it actually works very well.

The provided Eduard masks fit perfectly when masking the exterior of the clear parts. If you look carefully you can also see the pre-painted PE used on the canopy internal framing as well as the three rear view mirrors from the PE set.

When it first came out I eagerly grabbed some rolls on the new Tamiya Masking Tape "for Curves". This is a vinyl tape and is able to bend (without kinking) far more effectively than the more common yellow paper based Tamiya tape. I don't use the vinyl tape very often but found it worked perfectly on the side sills of the cockpit to help me accurately mask the subtle curves found here. The rear bulkhead was masked using a circle template to cut normal Tamiya tape to shape.

The main landing gear of the F-8E is pretty simple consisting of two main load bearing struts with a third smaller retraction strut. The detail on the Hasegawa parts is nice and is accurate for an F-8E (not so for a later model F-8J) and I proceeded to clean up and assemble the gear prior to painting. I did want to add a little more detail in the way of hydraulic lines and this was achieved using 0.25mm copper wire and thin strips of Tamiya cut..

Are you enjoying and finding value in this content? If so, please consider supporting my work by Buying Me A Coffee. Your support ensures that I can continue to provide high-quality, accessible content now and in the future, keeping this space free from distractions and focused entirely on the hobby we all love. Every little bit helps, and I truly appreciate your generosity!

The F-8C saw the introduction of the more powerful P&W J-57-P-16 engine. To assist in cooling the tremendous heat generated by the afterburner, Vought added cooling intakes to the rear fuselage on top of the afterburner cone. Hasegawa provides these in plastic but Eduard (not included in the Limited Edition boxing) produce much nicer parts in resin (648301). If you use the default position of the locating holes on the Hasegawa fuselage it results in the intakes sitting at the wrong angle relative to the tail and fuselage. The upwards angle shown in the before picture is incorrect and needs to be corrected (drill a second hole or just file out the original hole) to drop the rear of the intake so it sits aligned properly with the panel line and vertical tail.

With all the masking complete it's time for a final 'once over' of the model to make sure I have not forgoten anything before commencing painting. Primer has been applied to anywhere I have done seam or surface repair work to ensure all look clean.

The wing is not glued at this point as I plan to paint it separately (one of the benefits of the Crusader I guess). The wingtip navigation lights have been painted with Mr Color clear Red and Blue and then masked off.

As usual I spent quite a considerable amount of time checking and sharpening each of the panel lines and rivets across the surface of the entire model. From experience I know this is needed (especially on Hasegawa kits) to ensure the panel line washes can take hold properly down the track.

Milliput has been used in a few places (like on the base of the ventral fins and the flap join lines) to fill small gaps. Rather than sanding when dry I like to blend the Milliput whilst it is still workable with a damp cotton bud.

Painting starts with an overall coat of Tamiya Semi Gloss Black, thinned with Tamiya's own Lacquer thinner. I've used this method a lot in recent builds and I prefer it to the more popular pre-shading technique which focuses on only the panel lines. As I entered the painting phase I wanted to challenge myself to try out a few new techniques that I had seen used to great effect by other modellers. One such modeller is fellow Aussie, Ralph Reise from Garage Session Modelling. I really like the way that Ralph uses color to give a real depth to the models surface finish. This starts with the base coat and so I picked a couple of colours that seemed appropriate to randomly shade assorted panels.

I did not want to overdo the pre-shading work so intentionally kept it to a minimum. As I planed to use the Mr Paint acrylic lacquer paints for the final colors I knew that I could slowly build up the cover coats.

The lower surfaces of US Crusaders are pretty much universally white. I decided to not start with a stark white but instead chose a 'dirty' white onto which I could later apply full white to show some variation. This photo shows the result after a single light coat of Mr Paint 135 Insignia White. At this point you can clearly still see the pre-shading colors, perhaps a little too much.

The horizontal stabilizers on the F-8 are painted white top and bottom. I used the same pre-shading technique here as well. The best advice I can give is to use thin paint (Mr Paint is already heavily thinned out of the bottle which is one reason I like it so much).

At this point I have gone back over the entire wing again with the dirty white and then followed up with some pure white to highlight random panels and areas of the wing surface. I like the variation that we are seeing here already. If you look closely you can see some of the yellow and blue pre-shading as well.

Speaking with Ralph about how to start to give some depth to the white he suggested I begin by using a tan or buff color along some of the panel and rivet lines. This started to give the impressin of grime as well. Note how the center section of the movable wing has also been left much cleaner that the outer sections. The intention in all of this is to remove any uniformity. No aircraft paint finish should be one color or shade of color (well maybe show planes like the Thunderbirds or Blue Angels but these are not really workhorse aircraft).

The lower fuselage has received a similar treatment as the wings. I knew that much more grot was destined for this area later down the track so did not too get carried away.

The paint demarcation on the Crusader looks to be a hard edge. To simulate this I used Tamiya tape and for the tricky curve at the very rear near the exhaust I tried out some of the new Tamiya Tape for Curves. This is a vinyl tape (as opposed to the normal paper based yellow tape) and certainly does bend around curves a lot better than even the thinnest strips of traditional tape.

I applied the MRP-098 US Navy Light Gull Gray FS36440 to the upper surfaces, again building up slowly and then used assorted greys and buuf/tan to give the surface a lot of variation. I have found that it's ok to push this process to the point where it looks overdone because when you apply decals, washes and other weathering later on it all gets toned down.

A good shot of the extra riveting work I did to the upper wing surface. Adding extra detail like this helps to bring the model to life and when you paint it accordingly the results can be quite rewarding. There are no less than 5 colours and shades of paint applied here.

Are you enjoying and finding value in this content? If so, please consider supporting my work by Buying Me A Coffee. Your support ensures that I can continue to provide high-quality, accessible content now and in the future, keeping this space free from distractions and focused entirely on the hobby we all love. Every little bit helps, and I truly appreciate your generosity!

From photos it seems that most of the USMC Crusaders had the area around the gun muzzles painted in black (presumably to protect the aircraft skin). I once again reached for the vinyl Tamiya Tape for Curves which easily handled the curves here.

With the main painting complete it was time for a coat of gloss clear (Tamiya X-22 thinned with lacquer thinners). This protects the paint for the enamel wash and oil weathering to follow. Of course decaling happens before this but I was on a roll and forgot to take photos of the decaling before I got stuck into the panel washing. I have fallen in love with the MiG Ammo pre-mixed range of panel line washes. These are enamel based and come in about 20 different colors, more than enough for your panel washing needs.

I leave the panel line wash about an hour to dry (but cure) and then remove the excess using a dry paper towel and/or cotton bud. You have upto about 24hrs to be able to remove the excess without the need for thinners, which is very handy.

Don't forget get the panel lines and rivets over your decals. Nothing looks stranger than decals that seem to float above the surface of the model because panel lines stop at their edges. Also notice how the darker panel lines already are tending to tone down the previous painting shading I did. It all needs to work together to look right in the end.

The decals provided in the Eduard Limited Edition boxing are designed by Furball Aero and printed by Cartograph. You could not ask for a better combination of accuracy and quality and as expected the decals all performed perfectly. The fit was spot on with even the tiniest of stencils behaving themselves. The bare metal exhaust section has been painted with Alclad Stainless Steel and and Blue-Black panel lines wash used (only on this area).

Even the tricky curves of the F-8 intake were no match for the Furball decals. The two part decal fitted perfectly with some Micro Sol solution needed to get them to snuggle down into the various lumps and bumps. Due to my heavy handedness I did tear one of the red decals and can confirm that Mr Color C327 Red is a perfect match for touch ups.

With the decaling complete and the first round of panel washes in place it was time to try some new techniques. I wanted to make the surface of the Crusader look suitably grotty and so I now turned to another MiG Ammo product I have recently picked up, the Oilbrusher. As best I can tell the Oilbrusher is basically the same as other oil paints but

packaged in a more convenient way for us modellers. They come with a built in brush and a self sealing bottle to minimise mess.

I applied several dots of the 'Starship Filth' color on the surface of the model and used a brush loaded with white spirit to move the oil paint over the surface of the model. I found this gave my much better control than mixing the oil with thinner and applying as a wash. The result I was after being a very light covering of a grimey colour, remembering that anything applied over white will quickly overwhelm the base color if too heavy. After this dried (overnight) I loaded a brush with some heavily diluted black oil paint and then flicked it using a toothpick randomly over the surface to simulate oil spots. Less is more with this technique I have found (especially on aircraft which don't get as dirty as their armour cousins)

For the backend (aft of the main wheel well) I wanted to get seriously down and dirty. I had seen an interesting technique described by Daniel Zamarbide (of AK Interactive) in his FAQ book which used the airbrush to blow paint onto the model surface. Basically you mix up the desired colour (in this case I used one of the pre-mixed MiG enamel panel washes) and load up a paint brush. Hold this over the model surface and then point your airbrush and blow the paint off the brush in the direction you want to simulate oil stains in the airflow. I experimented with a combination of paint thinning and air pressure and found you could get quite a variation on the model surface. I think the result here is probably a little heavy handed but ok for my first time.

Oil paints were also used on the upper surfaces but not as heavily as underneath. I have learned that its very easy to overdo this technique and it's going to take me a while to get comfortable with it. One thing to remember is that you can use white spirits and a cotton bud to remove the oil if its too overpowering.

Furball include a set of their super convenient "canopy seal" decals in the kit. Aircraft often use putty around the canopy windscreen and canopy as a seal. This is often a different color and on the Crusader is a lemon yellow color as shown here. I applied the decal after I removed the paint mask. As usual the fit was spot on. Also notice the staining around the gun muzzles. This was airbrushed using heavily thinned Tamiya Flat Black. Stains like these were quite distinct on Vietnam era F-8's, particularly the USMC squadrons who used guns as during ground attacks.

With weathering mostly done I could begin the final assembly starting with the main gear. Due to my earlier prep work the gear struts simply slotted in and were secured with two part epoxy glue. I use this type of glue as it gives an extremely strong bond and several minutes of adjustment time (unlike super glue).

The Eduard resin exhaust (648302) was now installed in the rear fuselage and the cooling intakes (648301) glued to the upper fuselage. I kept the shading on the cooling intakes different to the fuselage sections to once again provide a contrast.

A final look at the cockpit interior before I installed the Aerobonus pilot with seat. I think that the Eduard pre-painted PE works well if the main color of the cockpit is black as seen here. When they try and match any other color I find the results are not as convincing. You can also see the Furball canopy decals from another angle.

Once the wings were fully weathered (I could have possibly gone harder here) the pylons with their Mk.82 bombs are installed. The whole wing assembly was now mated to the fuselage and secured with epoxy glue (to allow some alignment time).

It was not only the aircraft that got the weathering treatment of course. I once again used many of Daniels techniques to weather the Mk.82 bombs and the Zuni rocket pods using pigments to simulate a dirty and faded finish. The RBF tags are the Eduard fabric style and hang way more convincingly than the earlier PE versions. The bomb graffiti was taken from an old sheet I had by Gekko Graphics. I added the bomb fuse wires using 0.125mm coper wire and chips and scatches (on the pylon and bombs) were added using a HB pencil (with a very sharp tip).

Here are a selection of photos of the finished model. I am very happy with how it all turned out, especially since many of the new techniques I tried were out of my comfort zone. I always remind myself of the old saying 'you can't make an omelette without breaking some eggs' :)

CONCLUSION - Eduard 1:48 F-8E Crusader (ED11110)

For some time now Eduard have been reboxing Hasegawa kits, adding a bunch of resin & photo-etch goodies and marketing them as 'Limited Edition'. They come at a premium price and for the most part I personally have not been tempted by these kits, mainly because I had the original Hasegawa releases with heaps of addons already. When the F-8E Crusader boxing came along I paid attention as I have always liked the Crusader and figured that doing a build & review would be a great way to motivate me to finally get one finished.

I was immediately attracted to the heavily worn and bombed up finish of the Da Nang based US Marine F-8E's and given the Furball decal sheet that Eduard includes in the box includes a VMF(AW)235 'Death Angels' option I had my plan. Along the way I used a bunch of extra addons (like an Aerobonus Pilot, some Eduard Mk.82's etc) above and beyond what was included and I took the opportunity to stretch myself by trying out many new weathering techniques.

The Hasegawa kit has always built into a very convincing model of the 'Last of the Gunfighters' and for those of you have never picked one up the Eduard boxing maybe a good option. In my opinion it has enough extra's to justify the 'Limited Edition' asking price and will probably remain the best option in 1:48 for some time to come.

Are you enjoying and finding value in this content? If so, please consider supporting my work by Buying Me A Coffee. Your support ensures that I can continue to provide high-quality, accessible content now and in the future, keeping this space free from distractions and focused entirely on the hobby we all love. Every little bit helps, and I truly appreciate your generosity!