Curtiss SC-1 Seahawk

Halberd Models

1:48

Reviewed: Apr 2023

Halberd Models is a Ukrainian based company who specialise in detailed resin conversion sets for aircraft. Having released some beautiful conversions based around the P-51 Mustang family, Halberd have now released their first full kit in resin.

The subject of this new model is the Curtiss SC-1 Seahawk in both 1/48 and 1/32. A quick search on scalemates.com reveals that a previous (resin) kit of the SC-1 was released in 1997 by Signifier and that Halberd will be the first (and only) kit in 1/32.

Many of the Halberd conversions have been "limited editions" and I'm not sure if the same will be true of the SC-1 kit but I hope not as I'd encourage as many modellers as I can to purchase this lovely kit of an interesting aircraft in support of this company.

The kit in 1/48 is USD$100 and in 1/32 is USD$160, so they are not cheap, however I hope that by the time you reach the end of my review you will agree that what you get for the money is actually pretty good value.

The Curtiss SC-1 Seahawk was the last fixed wing scouting aircraft produced for service on the US Navy’s battleships and cruisers, and entered service late in 1944. The existing Curtiss SO3C Seamew and Vought OS2U Kingfisher were gradually replaced by the Seahawk in the late stages of the war and into peacetime.

The SC-1 was an all metal construction, cantilever low wing monoplane, with dihedral on the outer panel of the wings, a straight leading edge and tapered trailing edge. The wings could fold to reduce storage space on the ships. As a floatplane it had a single central float and wing tip stabilisers. The landing gear could easily be swapped between the two types. The float could also carry extra fuel. The prototype was powered by the Wright R-1820-82 Cyclone 9 radial engine. It was designed to be as simple to produce as possible, and a large number of them would be built in the last year of the war.

Losses with the "Seahawk" were high, mostly caused by the extremely hazardous conditions in which they operated. Too hard a water landing and the engine would drop, the propeller cutting through the float with several mishaps attributed to a faulty auto-pilot system. Aircraft and pilots were lost due to unknown landing accidents and it wasn't until one pilot "walked-away", that it was discovered that the auto-pilot was taking over on landings. As a result, all automatic pilot systems were made inoperative on all SC's. During the height of their career, crews aboard ship looked with pleasure at the "Seahawks" aft on the catapults as their "Quarterdeck Messerschmitts".

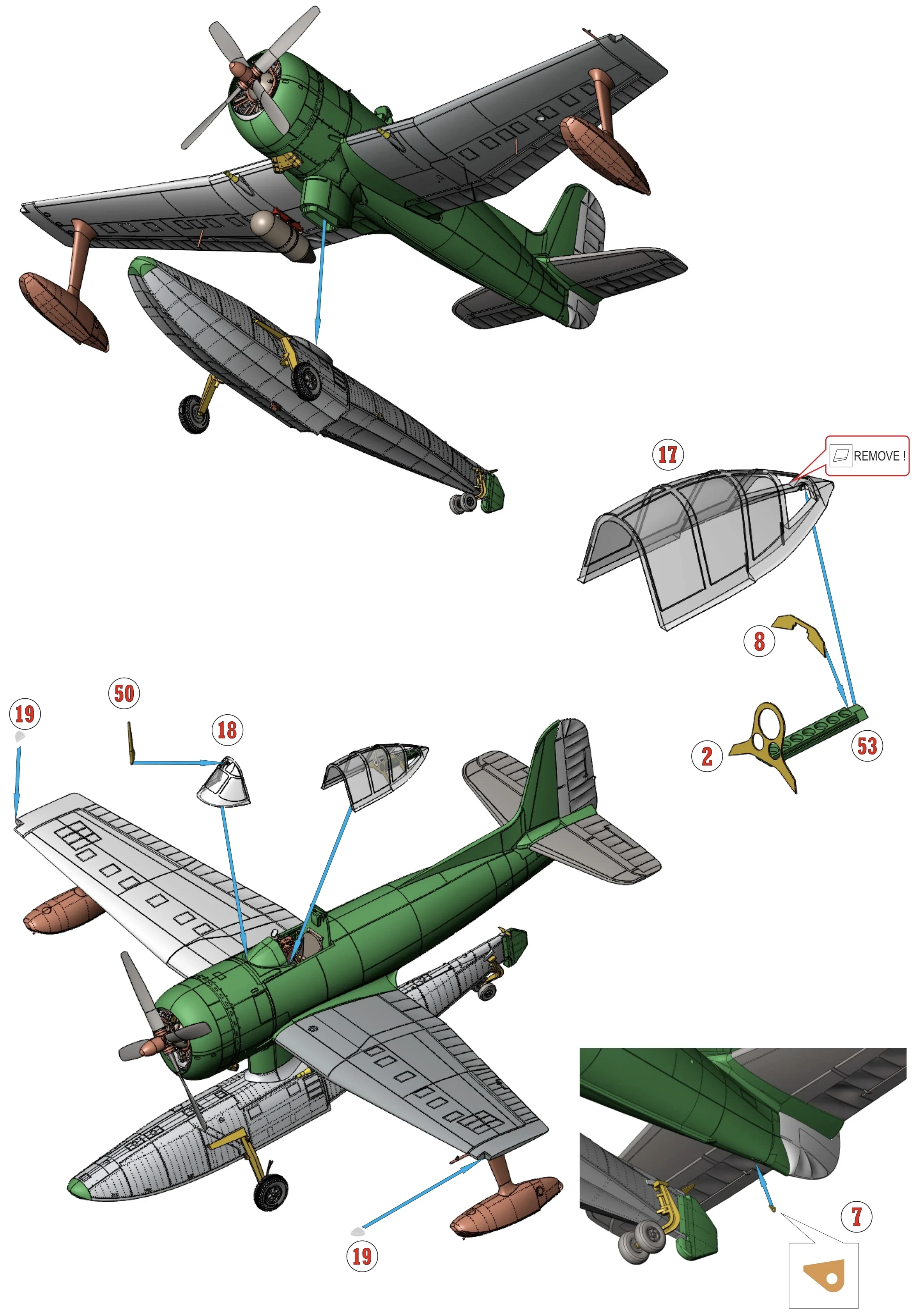

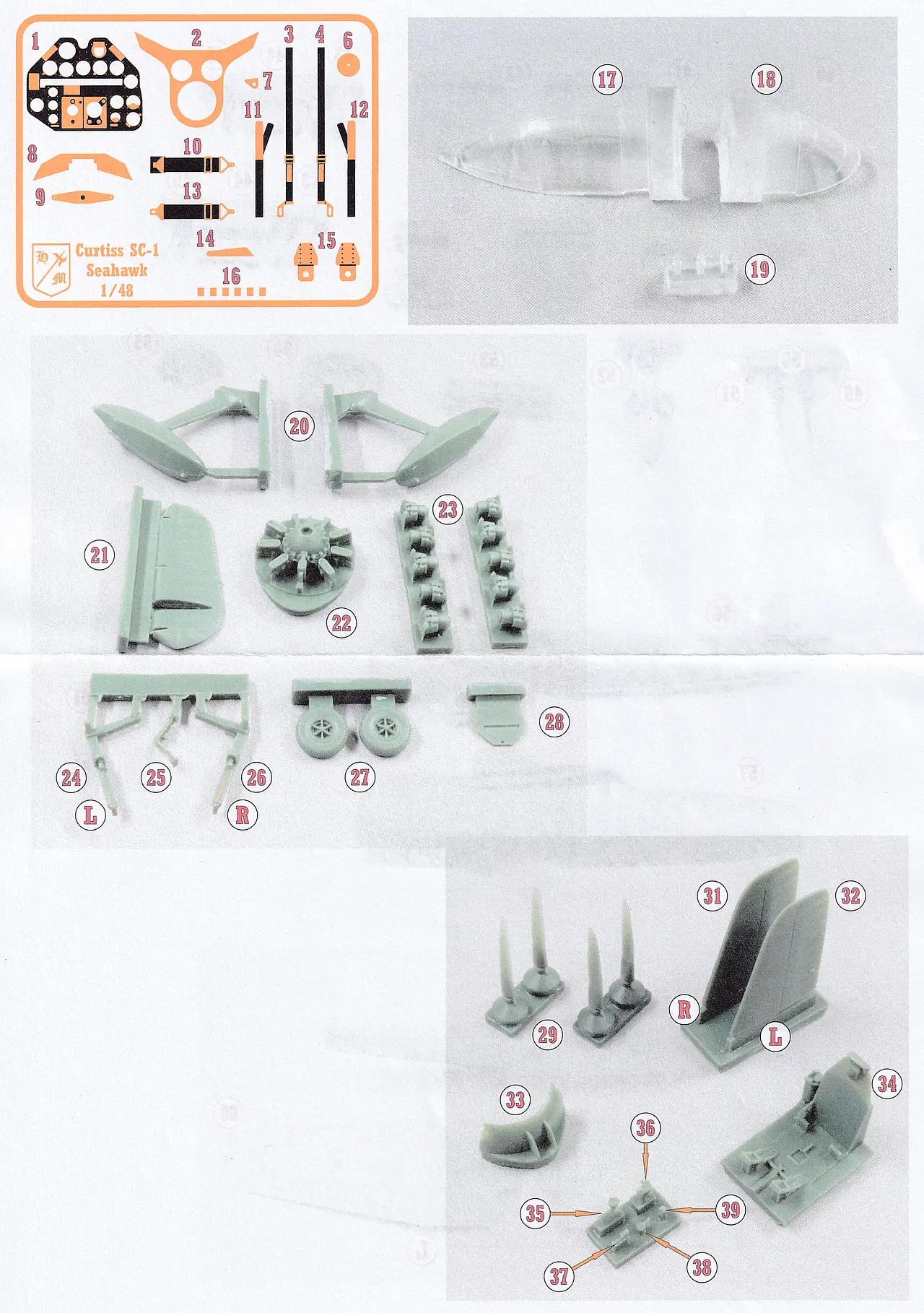

IN THE BOX - Halberd Models 1:48 Curtiss SC-1 Seahawk

For pretty good reason, all-resin kits are traditionally considered by many to be the purview of advanced modellers. Resin is typically harder to work with and historically resin kits have been made by small "back yard" manufacturers in a short run approach. Quality is typically rough and modellers really only resort to a resin kit if no other options are available. In truth until I came across Halberd I pretty much felt the same.

As luck would have it I recently acquired a second hand Halberd "Cavalier Turbo" Mustang conversion set in 1/48 for the Eduard P-51 kit. I was immediately blown away by the level of detail and quality in the resin parts, with the surface detail of the Halberd parts being indistinguishable from the original Eduard parts. I started to dig a bit deeper into the Halberd catalog and ended up ordering more conversions (Piper Enforcer) and eventually when they announced the SC-1 Seahawk I was confident enough in the quality of their work that I had no hesitation in placing my order.

The first thing you notice about the Halberd resin is the sharpness of the surface detailing. The resin is blemish free and the calming green color highlights the casting quality really well. The main float is a good example of the subtle and in-scale rivet/panel line detail and this part is cast as a single piece being easily the largest (and heaviest) part in the kit.

The SC-1 Seahawk incorporated a full wing fold to allow the aircraft to significantly reduce its footprint when loaded on the ship. Seahawks did not operate from aircraft carriers and so space saving onboard a cruiser or battleship was paramount.

It's usual to expect that resin parts will be cast in a single (solid) piece. One innovation that Halberd has introduced across pretty much all of their sets is to cast their parts hollow, or much like an injection plastic part. A good example of this is the SC-1's fuselage halves. Aside from the thicker than usual wall thickness this looks, and behaves, much like any plastic kit. Alignment pins are included by Halberd and as we will see shortly the fit is excellent. Really the only difference we need to consider is with the type of glue we use to secure the parts.

Much like any plastic injection molded kit, resin castings will often have small amounts of flashing that need to be cleaned up prior to assembly. Small pour blocks will also need to be dealt with and these are something that is unique to resin casting although newer 3D printed parts also have cleanup needed for their supports. Having said that the amount of cleanup needed for the Halberd Seahawk parts was absolutely minimal.

Even before I cleaned up the small amount of flash the fit of the fuselage halves was close to perfect. Such precision is very rare on all resin parts due to warping and shrinkage being common problems. To their credit Halberd seems to have figured out the secret sauce needed to eliminate this challenge with their resin parts.

The U.S. Navy's new SC-1 'Seahawk,' a fast, single-plane scout-observation float plane climbs rapidly after taking off from the water. The plane is used by cruisers and battleships to spot gunfire, search out enemy ships and to rescue persons from the sea. The Seahawk is twice as fast as the 'Kingfisher' it replaces. (USN)

Of course there is more to a kit than how nice it looks in the box. A dry fit is the best way to understand how much a model is going to fight you. I was very happy when the wing tab slotted cleanly and firmly into the fuselage. No cleanup or preparation was needed by me to achieve this gap free result.

Halberd have opted to provide the wings extended, with no option in the box for a folded wing. I'm ok with this decision as adding a wingfold would have added considerably to the complexity of the kit and hence the $ cost. The surface detail is again very nice and the scalloped fabric effect looks accurate and not over stated.

Like all floatplanes that have a single (central) main float, smaller outrigger floats are needed on the wings to stabilise the aircraft on water. Both of these parts have been cast by Halberd as single pieces and will require a small amount of cleanup to remove the molding flash and pour blocks. A good quality razor saw will be your best friend at time like these.

A US Navy Curtiss-SC-1 Seahawk is catapulted off the battleship USS Iowa BB-61 (USN)

The cockpit interior is very well detailed and comparisons to USN photos reveal that Halberd have done their homework. In this day of 3D printing it's good to see someone still making masters the old fashioned way. One thing that stood out in the instructions is the complete lack of color callouts. This is not just for the cockpit but is omitted from all the assembly instructions.

I could only find black and white photos of the cockpit interior but I think it's safe to assume the main color would have been Interior Green with the consoles plates in black.

The small brass photo etch sheet includes the main instrument panel, seat belts and other small components from around the airframe that worked better in sheet metal than cast resin. The finish of the PE sheet is reminiscent of Verlinden and the belts in particular will benefit from being annealed prior to bending. The assembly instructions include numbered callouts for PE parts but no corresponding number is printed on the PE sheet like you would normally expect from say an Eduard sheet. This I guess is one of the small challenges found with these type of limited run kits.

The SC-1 was fitted with a Wright R-1820-62 Cyclone rated at 1,350 hp, which gave the Seahawk a respectable 313 mph (504 km/h) maximum speed. Halberd has not attempted to provide a full blow engine but more sensibly opted to detail the front face of the engine which is all that will be seen through the front of the cowling.

The engine assembly sequence is pretty standard with Halberd providing each of the nine cylinders separately. The pushrods are not provided in resin so you will need to use brass or plastic rod to fabricate your own. The ignition wiring harness is included but as with any radial engine you will need to add the ignition wires yourself if you so desire. I think it will be worth the effort as the front of the engine cowling is quite open and visible.

Ten cylinders are included (you only need nine) so you will end up with a spare in case you damage one during removal. The detail of the cooling fins looks nicely to scale and under a coat of paint and wash the detail will pop nicely.

Sometimes in all-resin kits the clear parts are provided in vacform clear plastic. Not so for Halberd as they have chosen to cast in clear the resin the windshield and canopy. These are very well done with no visible distortions or blemishes seen. A real testament to the skill of the Halberd resin casting team :)

The beaching gear for the Seahawk consisted of 'bolt on' struts and wheels. Looking closely at the struts you can see that Halbred have cleverly embedded brass (or copper) wire into the mold before pouring the resin around it. This will significantly add to the strength of the strut and help avoid sagging (or breakage) over time.

A U.S. Navy Curtiss SC-1 Seahawk sea plane rests on its beaching wheels at the sea wall, Naval Air Station Jacksonville, Florida (USA), in 1946.

The Seahawk carried an APS-4 radar pod under the starboard wing. The APS-4 was a lightweight air-to-air and air-to-surface radar with a detection range for large ships of about 15 miles (24 km), and about 5 miles (8.0 km) against aircraft. It could also detect coastline at approximately 75 miles (121 km). The rudder is provided as a single piece and incorporates some very realistic fabric ribbing.

A rather tired-looking SC-1 Seahawk from the battleship USS Iowa (BB-61) after the ship was paid off into reserve in 1949. Note the use of post-war national insignia (USN)

Keen to see how the major parts of the kit mated I was easily able to use nothing but tape to dry fit them. Across the board I found no issues with achieving gapless joins between the fuselage and wings/tail and main float.

The pilot gives a "thumbs-up" signal to beaching crew who are preparing to launch the SC-1 into the water at a Pacific base, circa 1944-45. Note the white APS-4 radar pod under the wing and insignia of Scout-Observation Service Unit One (SOSU-1) on the nose. The beaching gear is marked "SOSU-17" and "VCS-10".

The engine fits snugly within the fuselage halves and will be worth your time detailing as it is very visible on the finished model.

Some filling of the wing/fuselage join will be required on the lower flap. Curiously the fabric flap does not extend this close to the fuselage on the upper wing so I'm not sure if Halberd got this wrong or on the real SC-1 the top and bottom were different.

A final dry fit test of the horizontal tail plains. The control surfaces are molded in place and a slightly different batch of resin must have been used (hence the darker color). The fit once again is excellent.

COLORS & MARKINGS - Halberd Models 1:48 Curtiss SC-1 Seahawk

Halberd provide a total of four (4) marking options in the kit, which for a limited run kit is very generous. This gives a good choice between the early 3 tone scheme (intermediate / sea blue over white) or the later (late/post war) dark sea blue over white. These are pretty standard colors and most all model paint manufacturers include them in their range.

An SC-1 Seahawk launches from the catapult of the light cruiser USS Macon (CA-132) conducting Atlantic Fleet training exercises in April 1947. The 13,000-ton warship was still new; she had been commissioned two weeks before V-J Day in 1945. Her aviation department typically operated two floatplanes.

A pair of SC-1 Seahawks at rest on the deck of USS Missouri (BB-63) on Sept 2nd, 1945, the day of the formal signing of the Japanese surrender.

The color and register of the included decal sheet looks to be very good. The decals are thin and the printing very sharp. Carrier film is minimal and the opacity of the white seems good but you never really know until its off the backing sheet. Small details such as instrument dials and propellor logos are included to round this out as a thorough set of markings.

REFERENCE GALLERY - Halberd Models 1:48 Curtiss SC-1 Seahawk

Here are some of the better reference photos I found during my research. I include them here to make your (and my) life easier when we start building the model.

CONCLUSION - Halberd Models 1:48 Curtiss SC-1 Seahawk

Halberd have a real winner here. It's a great subject which has not been covered by any major injection company. The quality of the workmanship and resin casting is the best I have ever seen. I found none of the traditional potholes common on short run resin kits and in truth I would hold this kit up against plenty of plastic kits anyday.

Halberd have honed their skills in master making and resin casting over the years with some absolutely brilliant conversion sets so it's no surprise to me that their first full blown kit is so good.

The only thing that might give some modellers a moment of pause is the USD$100 price tag (plus shipping from the Ukraine) but given that I live in Australia (about as far away from Europe as you can get) and the package arrived safe and sound in under 3 weeks should make you feel comfortable about any transaction.

I'd never really read much about the SC-1 Seahawk until Halberd released this kit but I liked the look of the airplane and took a punt on the quality from Halberd. Needless to say I have not been disappointed and I would wholeheartedly recommend this, and any other kits from Halberd, to you all.

Are you enjoying and finding value in this content? If so, please consider supporting my work by Buying Me A Coffee. Your support ensures that I can continue to provide high-quality, accessible content now and in the future, keeping this space free from distractions and focused entirely on the hobby we all love. Every little bit helps, and I truly appreciate your generosity!

ASSEMBLY INSTRUCTIONS - Halberd Models 1:48 Curtiss SC-1 Seahawk